What is Air Source Heat Pump Cascade Systems?

As the demand for efficient and eco-friendly heating solutions grows, air source heat pumps have emerged as a reliable alternative for residential and commercial spaces.

Nowadays, although many people want to become a heat pump installer, there are still many people who have doubts about how to become a heat pump installer. The conclusion drawn from a recent report is that there are not enough qualified tradespeople to achieve the heat pump goals. The government plans to replace 25 million oil and gas boilers in the next 30 years. However, there are only 3,000 trained heat pump engineers in the UK.

To meet the requirements of the proposal, 4,000-6,000 professionals need to be trained each year, and it is estimated that 600,000 heat pumps will need to be installed annually by 2028. Due to a labor shortage in the construction industry, these numbers seem ambitious at best.

So, becoming a certified heat pump installation engineer seems like a promising job, but how to become a heat pump installer? While you may have thought that all it takes to become a heat pump installer is the appropriate training and skills, there is some bad news for you. Without certification, you won’t be able to succeed in this industry. Therefore, aspiring individuals are undergoing the necessary training and obtaining certification as heat pump installers. It’s as easy as taking a piece of candy from a toddler. So, in this article, we will explore the options you may have not only to become a heat pump installer but also a certified one. Please keep reading.

So far, you have learned about the incentives and policies that the government has put in place to overcome the incompetence of heat pump installation companies. Now, this has led to the requirement for installers to participate in the Microgeneration Certification Scheme (MCS). However, this scheme is targeted at companies.

The issue is that its objective is to have companies employ verified heat pump installers who have been thoroughly assessed in the processes involved in designing, installing, executing, and debugging heat pumps. Besides obtaining certification that demonstrates the necessary skills, there is no better way to prove your level of knowledge.

The path to becoming an heat pump installer involves gaining knowledge of technologies such as boilers, pipework, radiators, and heat discharge controls. The required experience should be based on precise sizing determinations, calculating heat requirements, and understanding the appropriate emitters for optimal operation. With this knowledge and MCS certification, you are sure to thrive in the heat pump installation market.

One major obstacle that businesses face when training to install heat pumps is the cost. The cost of acquiring heat pump installation qualifications is high, and MCS certification must be repeated every five years, with costs potentially reaching thousands of pounds. In the current environment, most tradespeople would not choose to take time off work for training.

Without cash incentives and support to encourage engineers to undergo additional training, the government’s targets will continue to remain unachievable.

For homeowners, cost is also a significant barrier, with installation currently costing around £10,000. This is simply unaffordable for most households, especially with the rising cost of living; heat pumps are low on the priority list.

However, there are various grants available for homeowners who wish to upgrade. Given the high demand for engineers, this may be an ideal opportunity to enhance your skills.

Shenling will be the best solution of how to use a heat pump in winter

The Microgeneration Certification Scheme is a systematic program that provides recognition to potential heat pump installers in the industry without them having to go through cumbersome certification processes. So, do not mistake it for a course.

Please keep in mind that MCS is company-oriented. Therefore, companies certified by MCS are responsible for the design and commissioning of the heat pumps and all sizing calculations. The installation part will then be subcontracted to you. This program means that you won’t have to deal with the paperwork involved in government incentives, as that falls under the scope of the MCS operator. Without a doubt, the MCS scheme sets guidelines for installers. They include:

However, it needs to be reiterated that the MCS scheme is company-oriented. As a potential installer, you would have to find a company under this protective umbrella. If installation is just one gear in the heat pump business for you, and you start uncertain about the local demand for heat pumps, then the MCS umbrella scheme can be helpful.

Build Reputation – Certification can better promote your expertise, and having the support of MCS means you will receive recommendations from scheme operators.

Build Experience – MCS-certified companies are responsible for system design. Therefore, for you, it means gaining experience in other areas without being affected by design.

Free Training – Under the umbrella scheme, heat pump companies will require you to participate in courses related to their specific heat pumps.

Considering a company with MCS certification as the right composite approach is worthwhile. It doesn’t exempt you from training, meaning you still have the opportunity to gain experience. As an added feature, the cost and duration required to become a single certified entity are reduced.

Even as a sole entity or micro-installation business, the MCS umbrella scheme can bring you to another level of fair competition. It overlooks larger companies and exists solely to uplift those demonstrating excellent skills and capabilities.

With such assistance, as an installer, you can undoubtedly gain better experiences at your own pace in a less risky environment. In the long run, you may enjoy the benefits of being MCS certified.

Market gaps mean more opportunities. Those willing to invest in additional training will gain more experience and higher credibility in the future.

If you’re an engineer, you may be closer to qualifying as a heat pump installer than you think.

If you’re a graduate or looking to change careers, you’ll need to invest more time in training. Before training as a heat pump installer, you’ll need to obtain qualifications as a gas or oil heating engineer.

This means finding training providers and completing ACS gas assessments, which include the installation of five boilers under supervision. If successful, trainees will receive the CCN1 qualification and can be listed on the Gas Safe Register. Once registered, you’ll be eligible to install domestic gas and oil heating systems.

There are various options for completing this certification, including fast-track routes, apprenticeships (6-25 weeks) (3-4 years), and university courses (3-4 years).

The route you choose will determine the qualifications you achieve and may include Level 2 or Level 3 NVQ or SVQ in plumbing and heating installation.

From there, you can choose to pursue additional training in heat pump installation.

Before we delve into the steps required to qualify as a heat pump installer, it’s worth mentioning the difference between air source heat pumps and ground source heat pumps, as this is where training costs start to increase.

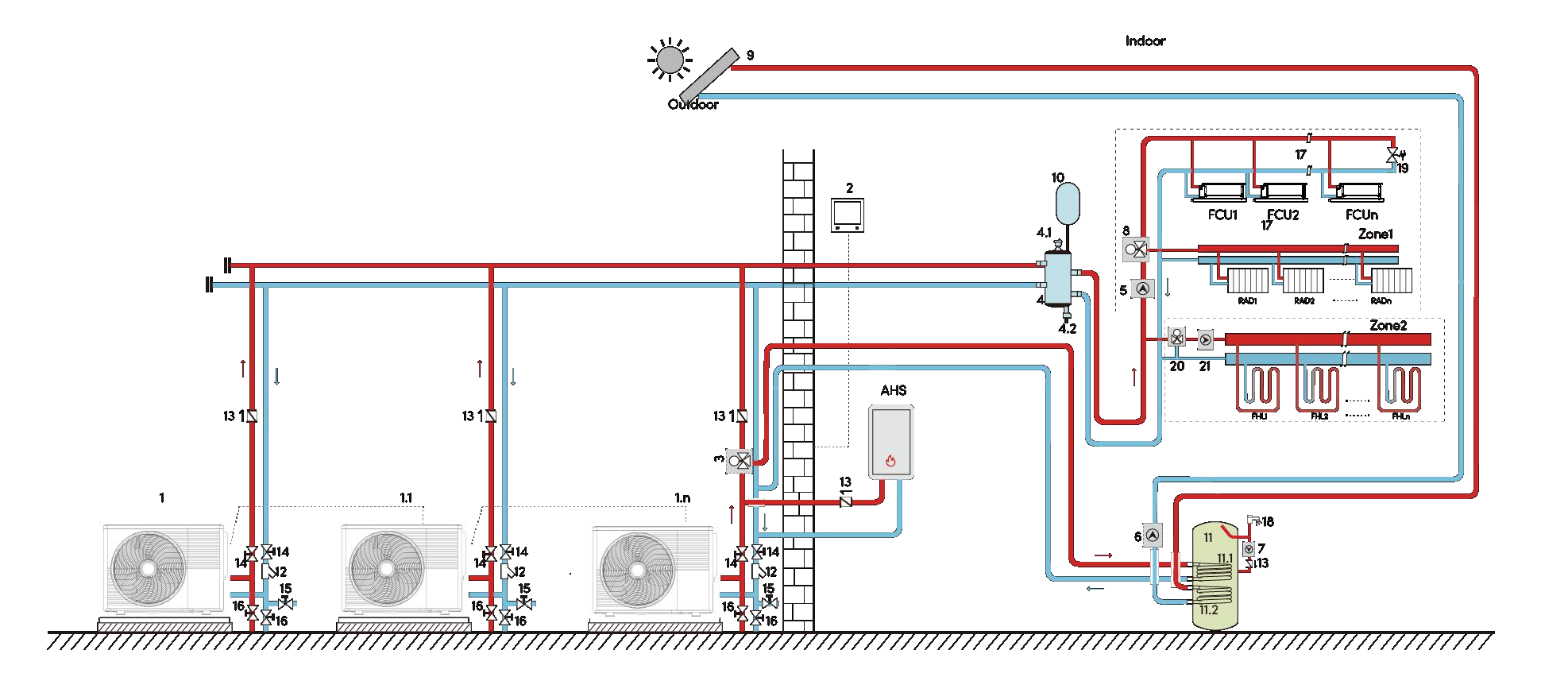

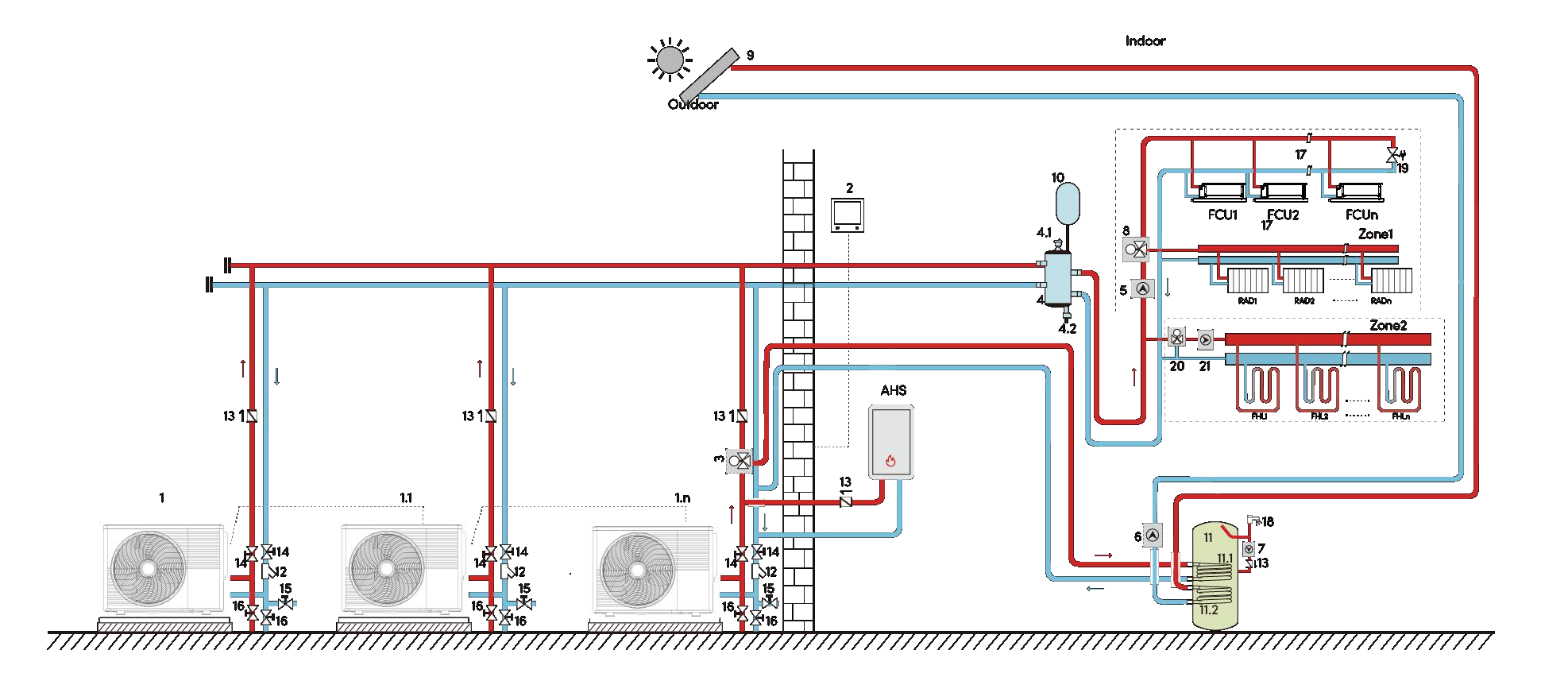

Essentially, air source heat pumps work in reverse to air conditioning. They draw in air from the outside and heat or cool the interior of a building. Ground source heat pumps extract heat from the ground to heat the building.

To undergo training in ground source heat pump installation, you must already hold qualifications in air source heat pump installation.

To enroll in an air source heat pump course, you must meet the following entry requirements:

An air source heat pump course typically lasts three days and combines classroom learning with practical exercises.

Upon completion, you can proceed to train in the installation of ground source heat pumps. The training takes two days, and upon completion of the course, you’ll receive an RQF Level 3 qualification.

At this stage, you’ll be fully qualified to install both types of heat pumps. However, additional electrical work may require a qualified electrician on-site.

As mentioned earlier, there are several stages to complete in order to become qualified to install heat pumps. The first stage is undergoing training as a gas heating engineer, and the options for doing so depend on your experience and background.

Once you become a qualified heating engineer, you can then undertake training in heat pump installation.

There’s nothing stopping you from completing the first stage of training, as it will qualify you to install air source heat pumps. However, domestic properties have different requirements. If you’re not also qualified to install ground source heat pumps, it may limit the number of contracts you can take on.

When aspiring to become an installation professional, there are several key areas to focus on, such as:

1. Assessment Knowledge

This is crucial in determining whether a heat pump installation is feasible. It involves examining the property’s size, energy consumption, energy sources, insulation, and radiators, and calculating the required size of the heat pump.

2. Heat Loss Calculation

This is determined by the radiators as well as the size of each room and windows. You can use online tools or traditional installation programs to perform these calculations. These calculations are vital for determining the operating costs of heat pumps and the amount they may receive from government incentive schemes.

3. Installation Expertise

This accounts for nearly 80% of the job. It requires knowledge of different heat pumps and boilers. However, dealing with piping and hydraulic systems is expected. At times, mechanical and electrical knowledge will be needed for power connections, instruments, radiators, and hydraulic balancing. Lastly, estimating noise levels will require calculations based on the distance from the property.

The annual income for domestic gas engineers ranges from £31,500 to £43,993, with an average salary of £35,000 (as of August 2022).

If you have received training in heat pump installation, the average salary can increase to £37,800. This means that the initial training costs can be recovered within 2-6 years, depending on the training route you choose. This does not include living and travel expenses, which should be factored into your budget if you opt for a 4-year training route.

With the continuous growth in demand, the average income in this industry may further increase.

If you are already a qualified gas engineer, it may be worthwhile to invest in additional skills for installing heat pumps. If you are a recent graduate or considering entering the industry, now is an excellent time for training. Opportunities in the renewable energy sector are excellent regardless of the approach.

So, there you have it. As heat pumps gain widespread recognition, the market for installers becomes increasingly competitive. Certification is therefore necessary.

For heat pump installers, obtaining MCS (Microgeneration Certification Scheme) certification is always a preferred and often mandatory choice. To obtain MCS certification, you must demonstrate your abilities and dedication to excellent craftsmanship, customer support, and continuous improvement.

If end-users want to access government incentives, MCS certification is a requirement. Therefore, cutting corners is not an option; you must receive the necessary MCS training and find an operating company to work with.

When installing split air source heat pumps, you will need F-Gas certification as all external and internal equipment must be connected to refrigerant pipes on-site. As a potential installer, you may need to consider the F-Gas qualification course. However, your employer may subcontract this aspect of the project to another properly prepared installer.

As the demand for efficient and eco-friendly heating solutions grows, air source heat pumps have emerged as a reliable alternative for residential and commercial spaces.

On December 5th, 2023, the signing ceremony for the ‘Shenling Special Air Conditioning and Ventilation Equipment Manufacturing (Gaozhou) Project’ took place in Gaozhou, Maoming. Notable

Embracing the Sustainable Future with R290 Heat Pumps In recent years, the quest for sustainable and environmentally friendly solutions has led to significant advancements in